- casa

- >

- Notizia

- >

- Laser Process

- >

- Common metal material laser cutting advantages

Common metal material laser cutting advantages

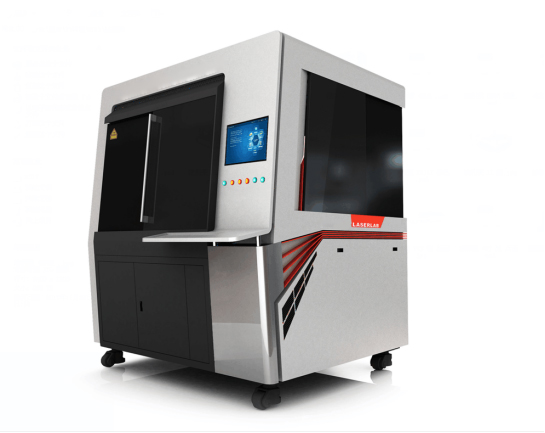

Metal manufacturing processes occupy an important market in industrial manufacturing. For most metal materials, regardless of their hardness, metal laser cutting machines can perform precision cutting without deformation. Metal laser cutting machine has won wide market prospects for its high flexibility, high speed, high efficiency, no need for mold casting, etc. The technology has a long life cycle and is widely used in sheet metal processing and advertising sign making. Various metal manufacturing industries such as glasses industry, subway parts and auto parts.

First, carbon steel.

The modern laser cutting system can cut the maximum thickness of carbon steel plate up to 50MM. The slit of cutting carbon steel by oxidation melting and cutting mechanism can be controlled in a satisfactory width range, and the slit of the thin plate can be narrowed to about 0.1MM.

Second, stainless steel

Laser cutting is an effective tool for the manufacturing industry that uses stainless steel sheets as the main component. Under the strict control of the heat input in the laser cutting process, the heat-affected zone of the trimming can be restricted to be small, so that the good corrosion resistance of such materials can be effectively maintained.

Third, alloy steel

Most alloy structural steels and alloy tool steels can achieve good trim quality by laser cutting. Even for some high-strength materials, straight, non-stick slash trimming is achieved as long as the process parameters are properly controlled. However, for high-speed tool steels and hot-die steels containing tungsten, there is corrosion and slag formation during laser cutting.

Fourth, aluminum and alloy

Aluminum cutting is a melt cutting mechanism, and the auxiliary gas used is mainly used to blow away the molten product from the cutting zone, and generally a good cut surface quality can be obtained. For some aluminum alloys, care should be taken to prevent the occurrence of intergranular microcracks on the surface of the slit.

Five, copper and alloy

Pure copper (copper) cannot be cut with a CO2 laser beam because of its high reflectivity. Brass (copper alloy) uses a higher laser power, and the auxiliary gas uses air or oxygen to cut thinner sheets.

Sixth, titanium and alloy

Pure titanium can be well coupled to the thermal energy of the focused laser beam. When the auxiliary gas uses oxygen, the chemical reaction is fierce, and the cutting speed is fast, but it is easy to form an oxide layer on the trimming edge, which may cause overburning. For the sake of safety, it is better to use air as an auxiliary gas to ensure the quality of the cut. The laser cutting quality of titanium alloy commonly used in aircraft manufacturing is good. Although there is a little stickiness at the bottom of the slit, it is easy to remove.

The laser cutting machine is a technological revolution of sheet metal processing, and it is the “processing center” in sheet metal processing. The laser cutting machine has high flexibility, high cutting speed, high production efficiency, short product production cycle, and has won extensive customers. In the market, the effective life of the technology is long. Most foreign steel plates with a thickness of more than 2 mm use laser cutting machines. Many foreign experts agree that the next 30-40 years is the golden age of laser processing technology development.