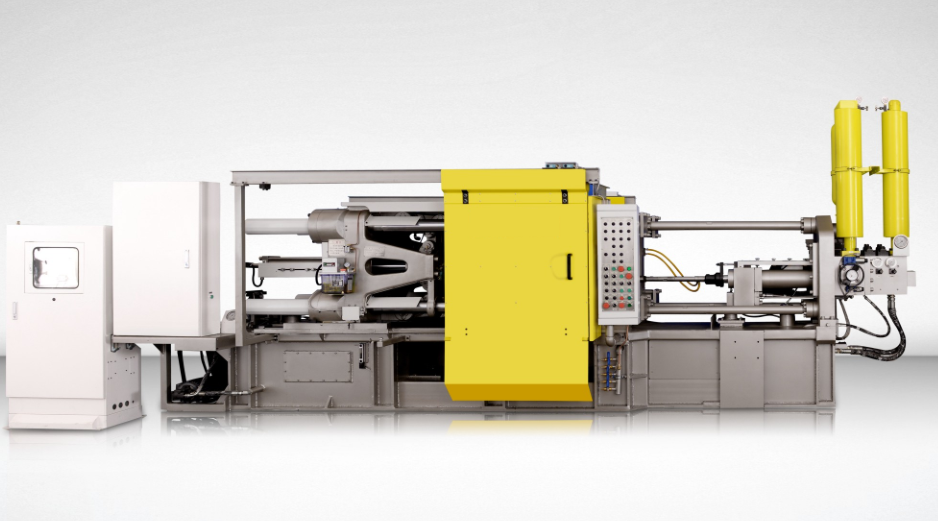

Macchina per pressofusione a camera fredda della serie Mega-Casting

Marca :Daseon

Origine del prodotto :Cina

Tempo di consegna :30 giorni

Le macchine per pressofusione a camera fredda della serie Mega-Casting con forza di serraggio di 20.000 kN gestiscono componenti complessi e di grandi dimensioni con precisione ed efficienza senza pari.

The advanced systems of our Mega-Casting Series cold chamber die casting machines represent a quantum leap in large-scale manufacturing technology. Combining industrial-grade processing capacities with innovative automation, these machines set new benchmarks for precision, efficiency, and versatility in high-volume production environments.

I. Core Technological Features

Quadruple Tie-Bar Design: Four φ280mm alloy steel tie bars with 3,000-ton preload ensure uniform clamping force distribution.

C/H Composite Beam Structure: 60% higher rigidity than traditional models, reducing platen deflection to <0.01mm.

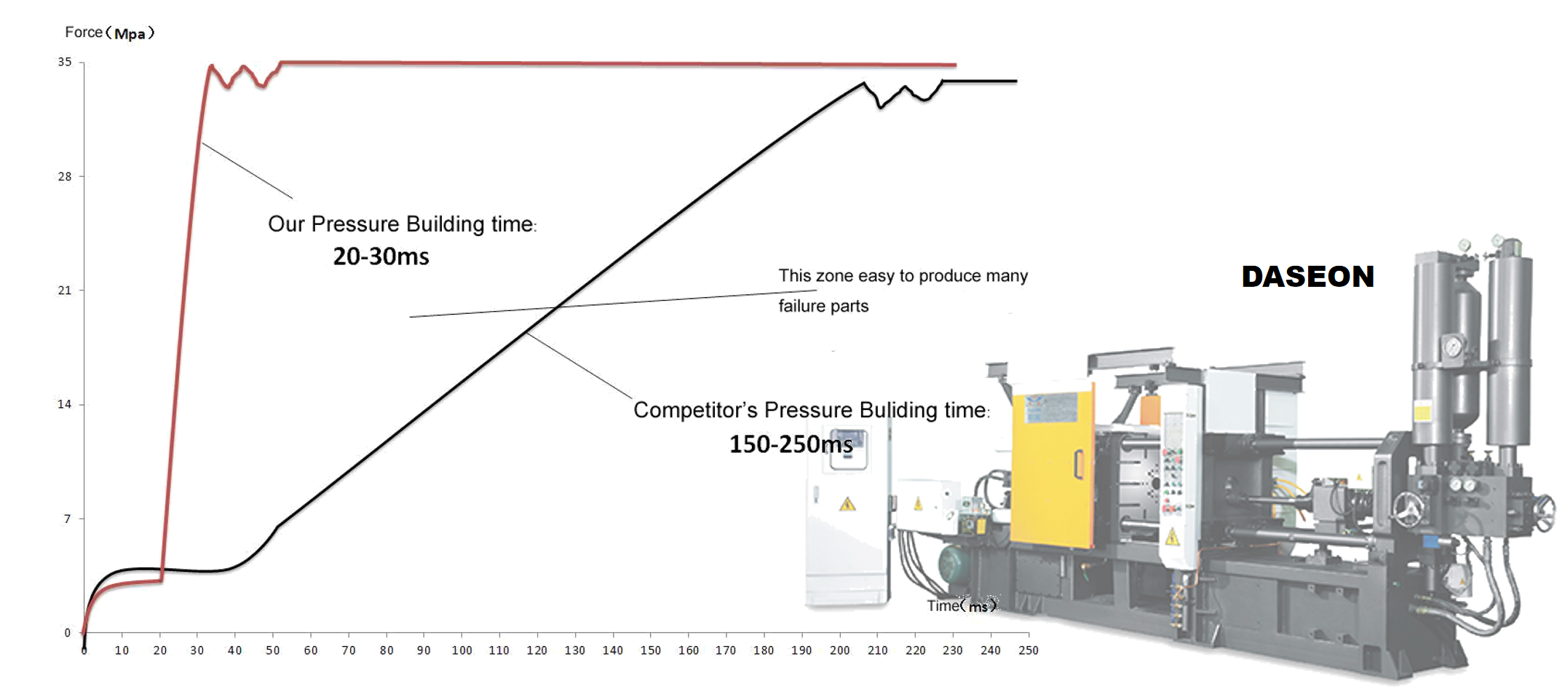

Dual-Plunger Technology: 0-8m/s adjustable shot speed with 113MPa pressure for complex geometries.Ensure structural rigidity and thermal stability even under extreme conditions.

Active Thermal Compensation: Real-time algorithm maintains ±2℃ temperature stability during 1100℃ brass casting.

Robot Interface: Standardized for fully automated production lines (loading, extraction, trimming).

Digital Technology: Real-time simulation predicts mold wear and process optimization.

II. Industrial Applications

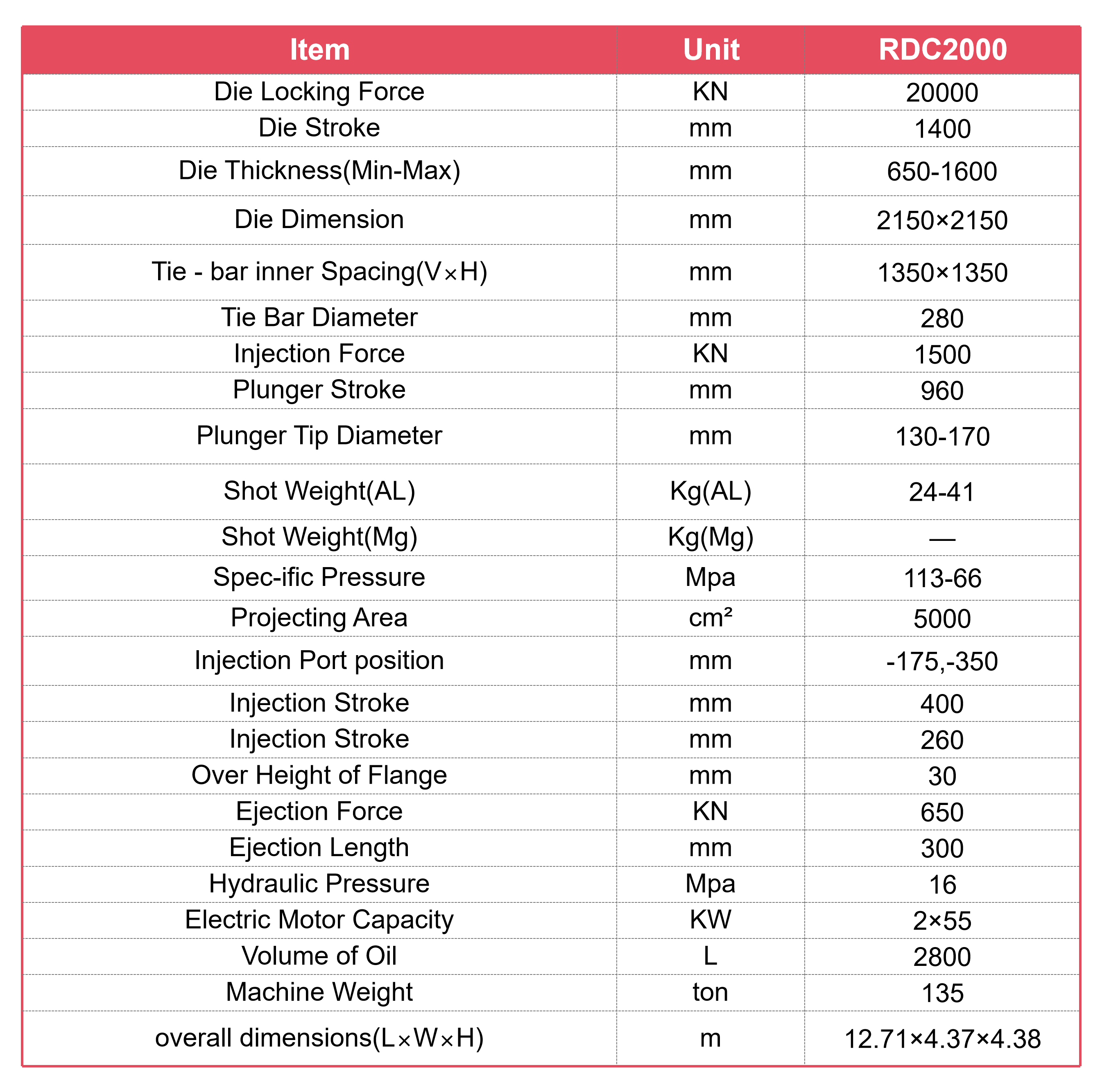

III. Technical Specifications

IV. Competitive Advantages

V. Why Choose Our Mega-Casting Series?

Parameter